Zebra 2017 Plant Floor Vision Study:

Zebra Technologies (www.zebra.com) has recently commissioned a global study to analyze trends and challenges that impact manufacturing companies. The study highlights a number of technologies that are now being implemented by companies to ensure quality and decrease cost of production.

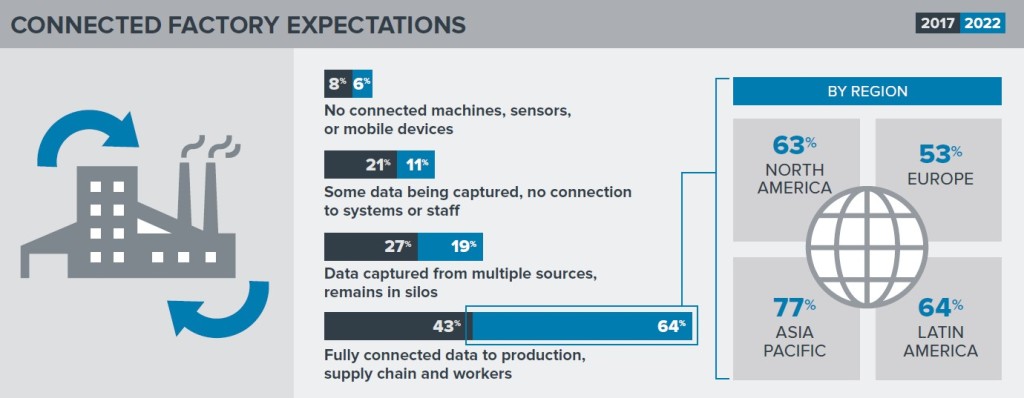

With a desire to connect every stage of the manufacturing process, including end-to-end supply chain fulfilment, manufacturers are turning to automation to improve quality and gain unprecedented visibility. Driven in large measure by globalization, intensifying competition and, perhaps most importantly, increasingly complex bills of materials due to rising customer demands for product variety — a connected plant floor has become a necessity to ensure high-quality products.

Manufacturers are adopting Industry 4.0 and the smart factory, in which workers use a combination of RFID, wearables, automated systems and other emerging technologies to monitor the physical processes of the plant and enable companies to make decentralized decisions. In the factory and across the supply chain, firms are also capitalizing on the Industrial Internet of Things (IIoT) to achieve real-time visibility into their goods, assets, processes and places.

At the heart of IIoT is the way companies capture and share data. The ability to have data about inventory needs immediately available in the cloud and available to both plant floor managers and suppliers offers unheard-of visibility that heightens operational performance.

Eagle helping create the Smart Factory:

Changing processes from customers has led to new requirements and demands for technology to be able to achieve operational goals. Eagle continue to develop products to help aid our customers create their smart factory. Several new solutions from Eagle are now available including;

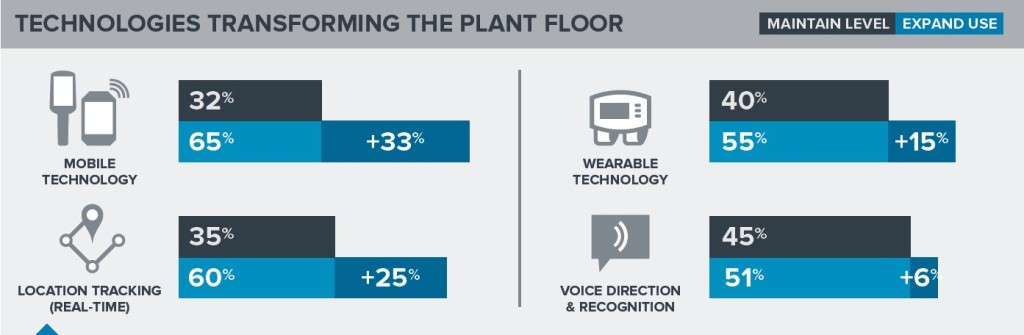

- New apps to support new mobile technology trends such as Android, and advances in devices such as the award winning TC8000 and TC7 Series from Zebra.

- While still a relatively young technology, wearables offer a plethora of opportunities to improve safety and increase productivity on the plant floor. Eagle has experience with devices such as the WT6000 from Zebra.

- Solutions that help automate Eagle transactions such as our Continuous Transaction Processor.

- Solutions that enable messages to be received from machines such as our charIOT solution

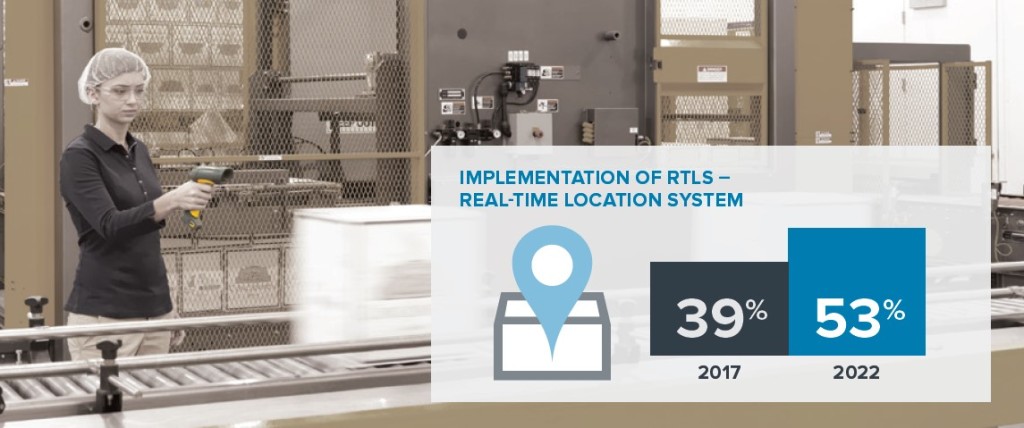

- Solutions that enable key assets to be tracked and located giving real time information to the factory.

Smart factories are the core of Industry 4.0 where real-time communication between the supply chain and the production line enable a high-level of automation and digitization. Making this possible are machines that can self-optimize and share data in real time to deliver better quality goods, unprecedented visibility and impressive cost efficiencies.

Manufacturers want real-time asset management and quality control of goods as they move through the production process. This is becoming increasingly important as the competitive landscape begins to encompass the importance of providing quality goods, tracking assets is taking center stage in the manufacturing industry. No longer can companies afford to track products solely at the Goods-In and Goods-Out phase of the process. According to survey respondents, only seven percent have real-time monitoring throughout the entire manufacturing process. However, 28 percent expect to add this capability within the next five years. Eagle are developing solutions for location tracking, please contact us for more information on our plans in this area.

For more information on the 2017 Zebra Vision Study please click here